Have you ever found yourself with workloads stacking up, missed deadlines, or your team always having a hard time keeping up with demand? Such exasperating hold-ups usually indicate bottlenecks in the operations of your business, some dark hole in your business processes that silently drains away business productivity and leads to higher costs.

Operational bottlenecks are those points in your workflow where one section is unable to keep up with the rest of your system, and slows the rest of your system. These bottlenecks can prevent efficiency, lower throughput, and frustrate employees due to outdated technology and manual processes, communication gaps, and limited resources. These bottlenecks can be identified and resolved to enhance the efficiency of the workflow by up to 30% percent, according to industry research.

We are going to discuss what operational bottlenecks are, how to identify them, and what can be done to eliminate them in this article. With the help of the optimization of processes, their automation, and efficient allocation of resources, businesses could simplify their operations, increase productivity, and avoid expensive delays. Bottlenecks can be supply chain disturbances, cycle time problems, or workforce productivity problems, but the bottom line is that to make workflows smoother, faster, and more efficient, the first step in this process is to understand what a bottleneck is.

What Are Operational Bottlenecks?

An operational bottleneck is a point in your business process where the flow of work slows down or stalls due to inefficiencies and outdated systems. Think of them as chokepoints where demand exceeds capacity, such as a slow approval process, outdated technology, or a single person holding up an entire workflow.

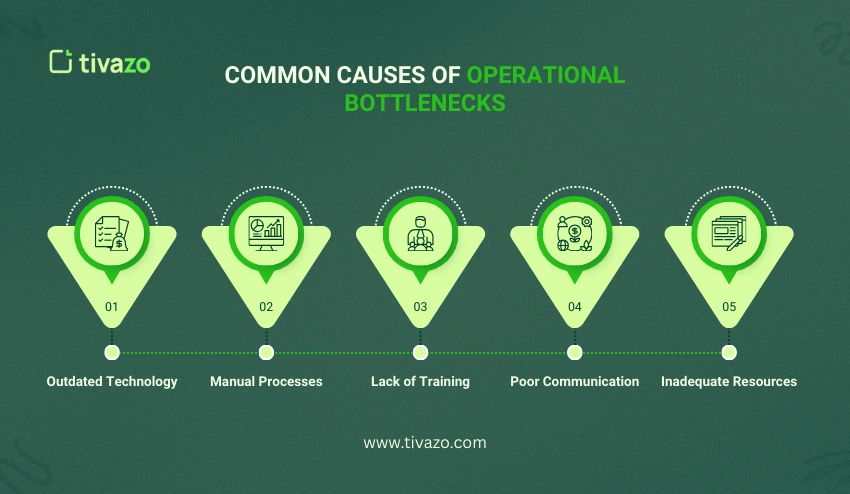

Common Causes of Operational Bottlenecks

It is important to determine the root causes of operational bottlenecks, as a business aims to enhance efficiency. Unless one is aware of the causes of these slowdowns, trying to correct the workflow can only do so temporarily.

1. Outdated Technology

Another significant cause of operational bottlenecks is old technology. Slow systems, systems that are incompatible, or those that are not integrated with current tools, require more time to accomplish a task, and the processes may stall and slow down the overall productivity.

Organisations with legacy systems usually experience fragmented workflows, which cause unjustifiable delays. A technological upgrade will assist in removing the operational bottlenecks through quicker processing of data, instantaneous cooperation, and interdepartmental integration.

2. Manual Processes

Operational bottlenecks are common with manual processes (e.g., hand-written forms or repetitive data entry). These are time-sensitive processes, subject to error, and can slow down workflows considerably.

When routine tasks are performed manually, employees take more time carrying out the routine tasks rather than addressing the strategic goals. These manual processes can be automated or streamlined, eliminating operational bottlenecks to ensure that teams operate more efficiently and minimize errors.

3. Lack of Training

Any lack of proper training can bring about unforeseen operational bottlenecks in any team. Workers who are not sure about a specific process or equipment can take more time to finish assignments and unintentionally delay work.

Regular training is an investment that would help staff know what to do and do it effectively. Lessening the skill gaps allows businesses to reduce bottlenecks in their operations and enhance the performance of the overall workflow.

4. Poor Communication

Ineffective interdepartmental or team communication is one of the causes of operational bottlenecks. Any miscommunication, not getting feedback within a short time, or a lack of information can stall a significant project.

With set communication channels and protocols, everybody is on the same page. It minimizes the potential bottlenecks in the operation due to discrepancies in priorities and ensures the processes are flowing in the right direction.

5. Inadequate Resources

The situation that is associated with weak operational bottlenecks is one in which the available resources are insufficient to satisfy demand. This lack of personnel, equipment, or software tools causes delays and inefficiencies.

These bottlenecks can be removed by evaluating resource requirements and making adjustments proactively. With proper support, the workflow will continue without any disturbance, and operations will be carried out efficiently and effectively.

Awareness of the prevalent causes of operational bottlenecks means that businesses can take positive measures to rectify the situation. Companies can eliminate these chokepoints and dramatically improve productivity by focusing on technology, processes, training, communication, and resources.

How to Identify Operational Bottlenecks

The identification of the operational bottlenecks should be attentively monitored and systematically organized. Identifying the location of delays, companies can make specific efforts to increase the efficiency of the workflow and decrease the number of unnecessary expenses.

1. Map Your Processes

One of the best methods to determine the operational bottlenecks in your processes is mapping. With a visual representation of the workflows, it is possible to observe the tasks accumulating in one place, or the tasks not being handed over at the required pace, or the approvals not being received at the required pace. By doing this, managers can easily identify bottlenecks and learn the impact of each step on overall productivity to promptly remove operational bottlenecks before they have a negative influence on performance.

2. Analyze Performance Metrics

Another important approach to finding operational bottlenecks is the analysis of performance measures. Some of the key performance indicators (KPIs) that can be used to quantify the efficiency of the working process include cycle time, throughput, and wait time. The tracking of these measures will be useful in identifying the slow-moving processes, which businesses can then systematically work on to solve operational bottlenecks and also enhance the overall performance of the processes.

3. Gather Employee Feedback

The employees usually know where the operational bottlenecks are located. Getting the staff to give feedback on workflow issues can help uncover any chokepoints that are not easily identified on process maps or data reports. With employee input, organizations would be able to pinpoint the areas of operations that may cause a bottleneck and provide practical solutions that would simplify day-to-day processes within the organization.

4. Use Technology

By capitalizing on technology, it is possible to significantly enhance the identification of the operational bottlenecks. Process tracking software, analytics platforms, and workflow management tools present real-time data on completion of tasks, resource allocation, and delays. By applying these technologies, businesses can easily identify bottlenecks in their operations and act accordingly to ensure efficient workflows.

A methodical way of finding the operational bottlenecks would make sure business organizations can identify those inefficiencies early and take corrective measures that work. A combination of process mapping, performance analysis, employee input, and technology will contribute to a complete strategy to eradicate chokepoints and enhance productivity.

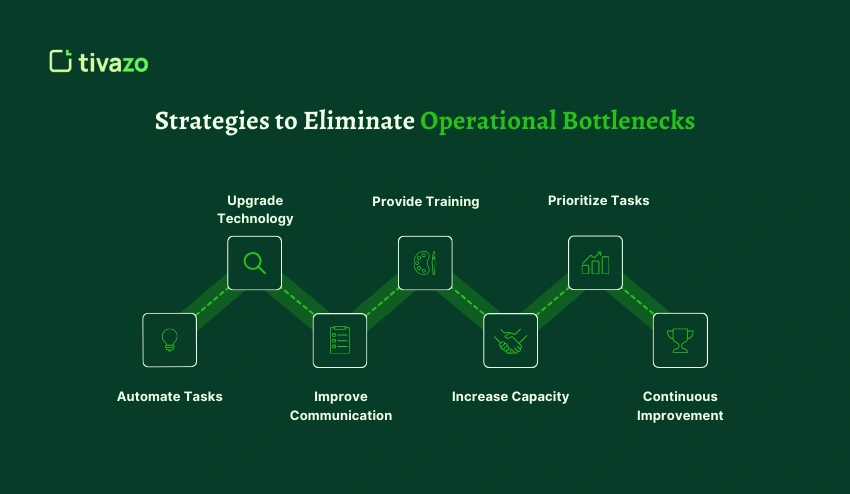

Strategies to Eliminate Operational Bottlenecks

Even the best-organized business processes might be slowed down by operational bottlenecks that affect productivity, employee morale, and customer satisfaction. After identifying such chokepoints, it is crucial to adopt specific strategies aimed at streamlining the workflows to ensure efficiency. Not only will solving bottlenecks fix delays in the short term, but it will also successfully avert delays in the workflow going forward, making your business agile and competitive.

1. Automate Tasks

One of the best means to remove operational bottlenecks is automation. Automating repetitive functions can help businesses reduce the manual workload and give employees more time to work on more important tasks and to solve critical issues.

Automation also reduces the number of human errors that normally occur behind the scenes to cause bottlenecks in workflow. Chores that previously had to undergo multiple levels of approval or had to be manually keyed into the system are now automated to help accelerate the process and eliminate delays.

In addition, automation offers real-time performance and notifications, allowing staff to identify problems when they are in their infancy and before they develop into significant operational bottlenecks. Such a proactive mode makes workflows efficient and smooth.

2. Upgrade Technology

Most forms of operational bottlenecks are due to outdated technology. Older systems generally cannot meet increased workloads, reduced processing rates, and lack integration features, which can lead to delays on an organizational scale.

A modern system will enable teams to do more work at the same time and help maintain smooth integration between the departments. More sophisticated tools also offer analytics that can be used to detect possible bottlenecks in advance before they can affect productivity.

Not only does upgrading technology solve current chokepoints, but it also makes the workflows future-proof, enabling an easier way to scale operations without introducing new operational bottlenecks.

3. Improve Communication

Lack of communication is likely to enhance operational bottlenecks through confusion and delays. Understanding between team members is poor, or the information they receive is inconsistent, and the team will spiral.

This is achieved by setting up formal lines of communication, weekly updates, and groupware tools to facilitate the flow of information across departments. This minimizes miscommunication and eliminates the interruptions in the workflow that are known to cause operational bottlenecks.

Open and efficient communication allows the teams to get on track with priorities, solve problems more quickly, and stay productive, which reduces the effects of bottlenecks on activities.

4. Provide Training

A lack of training is an unspoken cause of operational bottlenecks. Workers without an understanding of processes or knowledge of the tools can slow down processes without intention, forming bottlenecks.

Through extensive training, the staff is able to operate effectively and minimize any mistakes that lead to delays. Cross-training also allows for avoiding single points of failure, which makes workflows more robust.

Continuous skill enhancement not only solves the existing bottlenecks, but also prepares teams to respond to changing processes to reduce operational bottlenecks in the future.

5. Increase Capacity

When there are more demands than the resources available, the scarcity of resources usually leads to operational bottlenecks. Lack of personnel, equipment, or software assistance can result in delays and slow down operations.

Increasing capacity, either through new employees, new equipment, or new software tools, will allow the businesses to process larger workloads without slowdowns. This keeps important tasks running.

Anticipatory capacity management enables organizations to sustain a steady flow of operations, avoid bottlenecks, and react promptly to demand fluctuations, and is a way of ensuring that you maintain productivity.

6. Prioritize Tasks

In order to avoid operational bottlenecks that disturb the workflows, it is necessary to prioritize tasks. Teams are able to distribute time and resources efficiently when they address the most important activities first.

When priorities are made properly, there is less waiting caused by competing activities, and high-impact processes have been completed without delay. Choosing the right type of EOS can strengthen this prioritization framework by providing clear accountability and systematic tracking. It allows the managers to be aware of potential bottlenecks.

Prioritization and workflow visibility can help businesses run their operations smoothly, enhance productivity, and reduce the effect of operational bottlenecks on daily performance.

7. Continuous Improvement

There are also operational bottlenecks that usually keep coming and need constant attention. Periodically working through and identifying areas of inefficiency and streamlining processes should help prevent the emergence of new chokepoints.

A culture of continuous improvement will help make the employees proactive when it comes to identifying and addressing possible bottlenecks. This method is cost-effective in the long term.

Implementing the practice of continuous improvement through interventions, businesses can remove operational bottlenecks in the long run, automate workflows, and maintain high productivity rates in all operational departments.

Solution to operational bottlenecks should involve automation, technology upgrades, good communication, training, capacity management, prioritization, and continuous improvement.

Real-World Examples

1. Manufacturing Bottlenecks

When used in manufacturing, operational bottlenecks may significantly affect productivity and cost. One furniture maker, for instance, took a massive hit due to the slow entry of raw materials into the production process. This left supply chain management or resource allocation a chokepoint and machines and workers idle, which underscored how the bottlenecks of operations in supply chain management or resource allocation could interfere with the whole workflow. Recognition of such bottlenecks would enable the company to realign the material schedules and streamline operations in a bid to get the process back to normal.

2. Sales Operations Bottlenecks

Not only in the production process, operational bottlenecks can be in the sales and administrative processes as well. One example is a slow approval process to create discounts that held up a sales team, thus creating a bottleneck that could not close deals on schedule. These bottlenecks lowered the total throughput and generated lost revenue opportunities. These bottlenecks in the operations could be removed by the team through the automation of processes and approval workflows to enhance efficiency and customer satisfaction.

The Hidden Costs of Bottlenecks

Ignoring bottlenecks can lead to:

- Increased Costs: Delays can result in overtime, expedited shipping, and other costly measures.

- Decreased Customer Satisfaction: Slow service can lead to unhappy customers and lost business.

- Employee Frustration: Constant delays can demoralize employees and reduce productivity.

Conclusion

Operational bottlenecks are not simple nuisances, but big nuisances that can frustrate the growth and success of your business. These bottlenecks can be identified and resolved to increase efficiency, decrease spending, and increase customer satisfaction. Are you willing to get rid of the bottlenecks in your operations?