The modern business environment is characterized by a high rate of competition, which makes it impossible to run an inefficient business. Each minute, dollar, or other resource lost eats away at your bottom line and competitive advantage.

This is why it is important to enhance operational efficiency. Using efficient workflows, less waste, and more effective utilization of resources, firms can increase productivity and reduce expenses, and provide better products or services.

What, then, are the ways through which you can enhance operational efficiency in your business? Whether it is automation and data-driven decision-making, the optimization of supply chain management, or the training of the workforce, there are tried and tested strategies that can unlock the hidden potential. This article goes into practical advice and practical examples to get you to produce the maximum output with the least possible input to achieve sustainable growth and improved customer satisfaction. Are you ready to change your operations and improve the performance of your business?

What Is Operational Efficiency?

Operational efficiency is the capacity of a business to provide products or services to customers in the most effective way possible, keeping in line with quality and performance. It is basically an act of doing more with less; maximizing the use of resources such as time, labor, and capital so as to increase the output and minimize wastage.

IBM defines operational efficiency as making work more productive by reducing the number of errors, automating routine tasks, and streamlining the workflow. It is not only about cost reduction, but also about the intelligent use of resources that contribute to sustainable development.

Why Operational Efficiency Matters

The benefits of operational efficiency are not confined to the bottom line:

- Reduced Operating Costs: By utilizing the resources in a better manner, businesses cut down the costs of labor, materials, and energy.

- Improved Customer Satisfaction: Fast delivery times and quality products or services are produced due to efficient operations.

- Higher Profit Margins: Investopedia explains that when efficiency in operations is enhanced, companies are able to boost their profitability without necessarily increasing their prices.

- Sustainability: Achieving efficiency in the use of energy and materials helps to minimize environmental impact, which is becoming increasingly important to consumers who want to patronize environmentally friendly businesses.

Key Metrics to Measure Operational Efficiency

To improve operational efficiency, you first need to measure it accurately. Common metrics include:

- Operational Efficiency Ratio: This shows the ratio of operating expenses and cost of goods sold (COGS) to net sales, which is how much it costs to generate revenue.

- Inventory Turnover: The rate at which inventory is sold and replaced, which indicates efficiency in the supply chain.

- Accounts Payable & Receivable Turnover: Reflects the rate at which a firm settles its suppliers and receives payments from its customers.

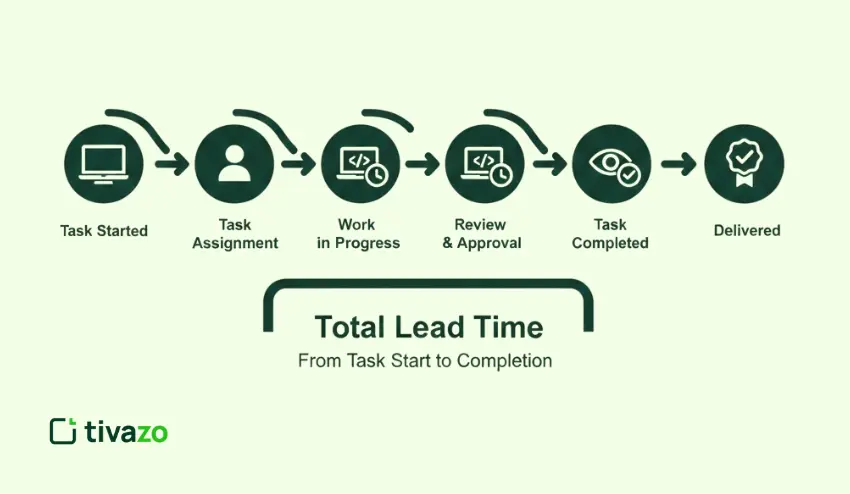

- Cycle Time: The overall time that a process or product takes to be delivered.

Using these KPIs, managers can identify bottlenecks and areas for improvement. According to Productive.io, balancing input costs against output results is vital for sustainable growth.

Proven Strategies to Enhance Operational Efficiency

There needs to be a strategic measure to enhance operational efficiency by streamlining processes and the best use of resources. Businesses can achieve high productivity and cost reduction by prioritizing their core areas, such as technology, workforce, processes, inventory, and data.

1. Leverage Automation

Automation is a great way to enhance operational efficiency through less manual input and error reduction. Companies that automate repetitive functions like data entry, invoicing, and reporting can release the time of their workers to focus on more strategic tasks. Robotic Process Automation (RPA) systems are designed to deal with such repetitive tasks, making them faster and more accurate.

In addition to mere automation, predictive maintenance is also important in the efficiency of operations. Real-time monitoring of equipment health will enable companies to preemptively schedule maintenance and avoid expensive downtimes, and extend the life of equipment, according to IBM. Such a proactive attitude maintains the smooth running of operations without any surprise disruptions.

One of the most distinctive lessons that most companies have learned is a combination of AI-powered analytics and automation. AI not only automates the tasks but also anticipates the bottlenecks in operations, and managers can respond to them proactively to ensure that the workflows are optimized.

2. Optimize Workforce

One of the secrets of operational efficiency is to make sure that employees are matched with tasks properly and not overworked. Workers who are overworked are less productive, more error-prone, and staff who are underutilized are wasted resources. Employing capacity management tools assists in aligning the skills to the job demands, which optimizes the use of labor. Organizations must evaluate their specific operational needs before purchasing software to ensure the selected tools integrate seamlessly with existing workflows

Another critical element is constant training. As pointed out by NetSuite, maintaining the skills of your employees and making them flexible will help your workforce to address the changing needs in a more efficient manner. Trained employees help in streamlining the operations and solving problems quickly.

By investing in workforce optimization, not only can efficiency be gained, but also employee morale and retention. When employees are encouraged and challenged in the right way, they will work effectively, and this will have an immediate impact on the overall performance of an operation.

3. Streamline Processes

The process of mapping workflows provides a visual representation of the process that is crucial in understanding inefficiencies and redundancies. End-to-end process mapping enables the identification of irrelevant processes or bottlenecks that lead to hindrance of business activities. Reviews and updates of the process maps are regularly done to keep the process maps up to date with changes in the business.

The implementation of Lean techniques and process mapping can also be used to remove waste and enhance flow, and this will directly result in better operational efficiency. Lean is concerned with the value creation and eliminating all that does not add value to the customer or the business.

One of the opportunities that is not used is the inclusion of customer feedback in the optimization of processes. By getting to know the customer perspective, one can identify the areas that require improvement, and one will end up with more productive and efficient processes that actually satisfy the needs of the clients.

4. Improve Inventory

Inventory management is a key aspect of operational efficiency, as overstocking uses up capital and exposes the inventory to obsolescence risks, whereas stockouts interfere with customer satisfaction. The use of just-in-time (JIT) inventory systems reduces the cost of carrying inventory by keeping it close to the demand.

The real-time tracking system allows businesses to see the movement of the inventory in their warehouses and in transit, thus increasing the accuracy and responsiveness. Such openness prevents delays and loss, which is inefficient.

Close cooperation with suppliers to reduce lead times and increase flexibility is another way of enhancing inventory management. IBM states that good supplier relationships are the pillars of supply chain efficiency in operations.

5. Use Data-Driven Decisions

The use of a data-driven decision-making process increases operational efficiency by converting raw data into actionable information. The uniformity in collecting and analyzing the operational data across departments reveals the trends and problem areas that would be overlooked by manual observation.

Visual dashboards enable managers to access the key metrics in real-time and react to the changes promptly so that the level of performance can remain high. Predictive analytics goes further to predict the changes in demand and resource requirements in advance.

ActivTrak states that companies that adopt data analytics have achieved immense productivity gains and cost savings, and data-driven decision-making is a strategy that is not negotiable in terms of organizational efficiency.

These are some of the strategies that have been shown to work, and when combined, they will ensure that a productive and resilient business is created. Through these methods, firms are able to prepare to be successful in the long term in a more competitive world.

Operational Efficiency Examples

The concept of operational efficiency is more apparent when you observe it in various industries. The following are some of the practical ways through which businesses improve their efficiency in operations:

1. Manufacturing Automation

Automation and lean manufacturing concepts are applied by automobile industries such as Toyota to make production lines efficient. This helps them to cut costs and enhance the quality of products by reducing waste and streamlining the assembly methods. This strategy has managed to make Toyota operational efficient in the industry, which has become an example to others.

2. Retail Inventory Management

Such retailers as Walmart apply advanced systems of inventory management based on real-time data and AI. Such systems minimize the amount of stock, they minimize excess inventory and stockouts, leading to low holding costs and increased customer satisfaction.

3. Energy Efficiency in Facilities

Hotels and commercial real estate corporations implement intelligent energy management systems to control and decrease energy usage. This saves on the expenses of operating and enhances sustainability, a win-win situation. Hotel financing lenders increasingly consider these efficiency improvements when evaluating properties, as lower operating costs strengthen financial performance and loan repayment capacity.

4. Customer Service Optimization

Most companies that have their business based on services use AI chatbots and CRM automation to answer basic questions quickly. This reduces the time of response and enables human agents to concentrate on complicated matters, increasing the efficiency and customer satisfaction as a whole.

5. Process Optimization in Logistics

The companies that deal with logistics can optimize the routes of delivery with the help of GPS tracking software along with free route planner app and data analysis helps in minimizing fuel consumption and delivery timeThis is not only cost-saving but also enhances the reliability of service, which pushes customer loyalty.

NetSuite describes these as examples of how customized approaches in various industries result in quantifiable results in the form of operational efficiency.

Common Pitfalls to Avoid

- Focusing Solely on Cost-Cutting: This can degrade quality and employee morale.

- Ignoring Employee Feedback: Frontline workers often have the best insights on inefficiencies.

- Underutilizing Technology: Some businesses hesitate to invest in new tools, missing out on efficiency gains.

- Failing to Track KPIs Regularly: Without consistent measurement, improvement efforts lack direction.

The Future of Operational Efficiency

As digital transformation accelerates, operational efficiency will increasingly rely on:

- AI and Machine Learning to automate complex decision-making.

- Internet of Things (IoT) devices to provide real-time operational data.

- Sustainable Practices to reduce environmental impact and costs simultaneously.

Businesses that adopt these technologies early will gain a competitive edge.

Conclusion

The need to enhance operational efficiency is a strategic priority that cuts across a business. With the help of automation, efficient use of labor and stock, data embrace, and process constant improvement, the companies will be able to cut expenses, grow productivity, and improve customer satisfaction.

Do you want to be able to raise your operational efficiency to a new level and give your business all of its potential?