What if you were operating a business where every hour of work brought you the greatest possible results, there would be no wasted efforts, no unexploited possibilities, and your costs wouldn’t increase exponentially. This is the effect that comes with mastering labor efficiency.

As a matter of fact, companies that are diligent about labor efficiency not only manage to reduce expenses but also become the most adaptable and productive players in the market. You can accomplish this by raising the effectiveness of labor hours, which in turn will lead to higher profits, better employee satisfaction, and a competitive advantage that is long-lasting.

It is a misconception that improving labor efficiency requires employees to exert more effort. In fact, employees need to be trained in ways that will actually save time, and they will hence work smarter and not harder. Managers can accomplish this goal through strategies that include better allocation of resources, improved time management, and automation of work that is both advanced and simple. Moreover, various surveys indicate that firms that are consistent in measuring and optimizing labor efficiency are capable of achieving even 20% more output per labor hour than their rivals who are not engaged in such actions.

This article presents labor-efficiency-boosting measures driven by data, from simplifying workflows to employee performance enhancement. No matter if you are managing a factory, a retail team, or a service operation, you will discover proven ways to increase workforce productivity and operational efficiency at the same time that you maintain quality and morale.

What is Labor Efficiency?

Labor efficiency is the extent to which an organization’s workforce is capable of turning labor inputs, such as hours worked, the level of skills, and effort, into quantifiable results. To put it simply, the measure shows whether the employees manage to produce the expected output in the time or utilize the resources that have already been allocated. When labor efficiency is high, tasks are done in a fast, precise manner and with very little wastage of resources; however, if labor efficiency is low, there could be all sorts of problems, such as inefficiency, delays, and improper use of resources.

In terms of operations, companies need to monitor labor efficiency with the help of different key performance indicators, which include the Labor Efficiency Ratio (LER), output per labor hour, and labor productivity analysis. The point in labor efficiency optimization is not to achieve faster work only, but rather smarter work through the removal of unnecessary tasks and by ensuring employee performance is in harmony with the goals of the organization.

What is the Labor Efficiency Ratio?

The Labor Efficiency Ratio (LER) is a key metric used to evaluate how effectively a workforce converts labor hours into productive output. It compares the standard hours required to produce a certain output with the actual hours worked, giving organizations insight into employee productivity and process efficiency.

What is the KPI of Labor Efficiency? (Labor efficiency KPI)

The Key Performance Indicator (KPI) for labor efficiency is a quantifiable measure that supports organizations in the evaluation of the effectiveness of their workforce in the conversion of labor input into output. The most common KPI for labor efficiency is the Labor Efficiency Ratio (LER), which essentially compares the standard expected hours for a task with the actual hours taken. When LER is high, employees are assumed to be carrying out their tasks more efficiently, whereas a low LER points out that there are inefficiencies that require the attention of the management.

Other important KPIs related to labor efficiency include:

- Output per labor hour – measures the actual production achieved for each hour of work.

- Labor productivity – an overall measure of how much output is generated relative to labor input.

- Labor cost per unit – tracks the cost of labor required to produce each unit of output.

- Rework or error rate – identifies wasted labor due to mistakes or quality issues.

By tracking these KPIs, managers can mobilize labor force productivity, upgrade employee performance, and improve operational efficiency. They can also pinpoint the bottlenecks, training gaps, and process improvements through which they can achieve these goals. Frequent checking of the situation ensures that labor resources are used effectively and provides for sustainable growth.

Did You Know

In Malaysia, value‑added per hour worked in Q1 2025 increased 1.0% overall, with the manufacturing sector rising 2.8% (to RM 56.4 per hour) and the services sector up 0.5% (RM 40.3 per hour).

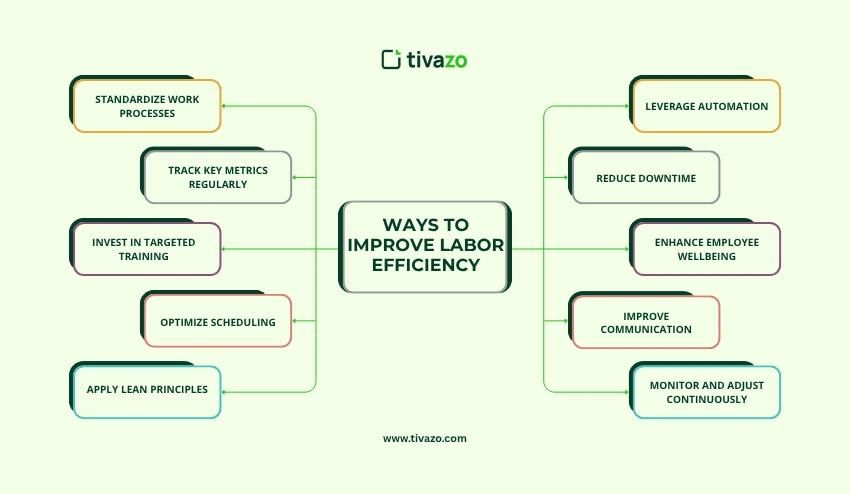

10 Proven Ways to Improve Labor Efficiency

Improving labor efficiency is a must for businesses that aim to get the most out of their labor hours while at the same time cutting down on labor hours. When the right strategies are put in place, it not only increases productivity but the employee’s performance and the overall operational efficiency are also improved.

1. Standardize Work Processes

One of the main things to do when you want to improve labor efficiency is to come up with standardized work processes. Standardizing work processes means that each employee’s task is done in a uniform way and, as a result, more work is done within less time and with fewer mistakes, which directly leads to a higher workforce productivity level. Based on the research of the industry, the companies that implement the standard operating procedures experience a significant reduction in labor inefficiencies and are less likely to face downtimes.”

Moreover, standardization is very important when it comes to training new employees, and labor utilization is also optimized for all shifts. Having clear process guidelines, employees get to know the expected standards, and thus, there is less room for confusion and mistakes that eventually may lead to operations being slowed.

In addition to this, standardized work gives supervisors the ability to precisely gauge labor efficiency ratios. It is through having a standard of hours per task that it becomes very easy to spot those deviations, which then lead to focusing on process improvement in the areas that matter the most.

2. Track Key Metrics Regularly

If one asks what the most important thing to do to improve labor efficiency is, the answer will definitely be monitoring key metrics. Those leaders who are using LER, output per labor hour, and labor efficiency variance as their key metrics can spot the inefficiencies that cause them in real time. According to studies conducted recently, the very same organizations undertaking these activities perform up to 20% better per labor hour than those that do not.

Another benefit that regular monitoring brings is the accountability that comes hand in hand with it, among employees. Staff who are given their performance data are better in self-evaluation, correction, and also the implementation of habits that are work-efficient, hence, employee engagement gets to be on a higher level.

Besides, the process of tracking metrics enables data-driven decisions for operational improvements. Companies can decide on the areas most suffering from the issue of efficiency that should be prioritized, and thus they can be certain to put the efforts into strategies leading to tangible work efficiency gains.

3. Invest in Targeted Training

Targeted training is one of the things that can make labor efficient, as employees will be the ones who perform the labor in the shortest time and at the highest level of accuracy. Training that focuses on reducing the time of machine setup, improving task performance, or being good at a new technology can lead very quickly to higher output per labor hour. According to Forbes, by investing in employee development, one gets a direct enhancement of workforce productivity.

Good training also makes employees more assured and hence more motivated, which is why mistakes will decrease and rework will need less time. The change in employee performance, which results in lower labor costs and better resource utilization, is the direct impact made by employee performance.

Moreover, continuous training gives you the assurance that your team will not lag behind in the progressively changing work practices. Skill acquisition alongside process modernization allows companies to sustain the rise in operational efficiency for the long term.

4. Optimize Scheduling

Good scheduling can bring about a significant change in labor efficiency. Matching work shifts to the level of demand allows employees to have a proper balance of work and rest hours, which is a great way to increase productivity hours. It has been found that companies that schedule their employees efficiently are able to increase the output per labor hour, and at the same time, they save money on overtime by paying fewer hours.

By cross-training workers, a company gains the necessary flexibility to meet peak demand, and at the same time, it is sure that labor utilization is well-balanced between different tasks. This strategy releases little to no time between periods of work, thus ensuring production is not stopped.

Besides, efficient scheduling results in the uplift of the work environment since the staff experience a more predictable and manageable workload fluctuation. Workers who are satisfied with their jobs generally tend to be more productive, which in turn leads to the overall improvement of employee performance and the saving of labor efficiency at a high level.

5. Apply Lean Principles

Adoption of lean procedures such as 5S, value-stream mapping, and takt-based workflows may significantly increase labor efficiency. Lean methods do away with wastes, lessen intermediary steps, and simplify processes without increasing labor costs, thus increasing productivity. In fact, the industry research reveals that companies that implement lean enjoy substantial increments of output per labor hour.

One of the ways that visual management tools, for example, process boards and clear instructions are used is that they keep employees updated on the flow of their work, and at the same time lower the variation in the performance level of the employees. This means that employee performance and work efficiency both get enhanced.

Moreover, lean practices provide a platform for a continuous improvement transition. They make it possible for a company to frequently locate bottlenecks and areas of inefficiency, thus keeping the company in top operational efficiency mode and at the same time ensuring labor is well utilized in all departments.

6. Leverage Automation

By doing automatic tasks that are repetitive and of low value, automation is able to upgrade labor efficiency, the idea that employees are to do only the higher-impact jobs. Whether it is data entry, inventory management, or the running of a machine in a production process, automation is there to lower mistakes and increase productivity. Hence, it is not surprising to read that upon the implementation of targeted automation projects, companies get to experience in the shortest possible period of time a variety of labor metrics showing improvement.

Besides, automation is a reliable method for delivering goods at an unvarying level as well as for recording labor efficiency ratios, since there will be fewer variations in the standard time. In this manner, human resource managers are facilitated in their work of reassigning the workforce to guarantee the highest efficiencies possible.

On top of that, by the marketing connection between automation and current operational methods, not only is the organization’s overall efficiency increased, but employees are able to produce better results, which ultimately results in both workforce productivity and the employees’ satisfaction getting a boost.

7. Reduce Downtime

Downtime is one of the major causes of inefficiency that is hidden deeply. Organizations, through the process of identifying causes such as equipment failures, missing materials, or bottlenecks, can take actions to make employees productive during their shifts. Addressing downtime, as per recent studies, can increase output per labor hour by 15%.

Preventive maintenance schedules along with real-time monitoring are the factors that help to reduce the instances of interruptions, thereby increasing the work efficiency and labor utilization. Employees would then be able to concentrate on value-added tasks instead of unnecessarily waiting or doing repetitive work.

Also, the decrease in downtime leads to the improvement of employee performance. A well-structured work environment will allow for the faster completion of tasks and with fewer mistakes, thus achieving sustainable long-term improvements in labor efficiency.

8. Enhance Employee Wellbeing

Employee well-being is one of the factors that significantly influences labor efficiency. It is very logical that a team under high stress, fatigue, or burnout will be less productive and more likely to make errors; thus, the overall workforce productivity is decreased. Research indicates that companies that allocate funds to wellness programs and balanced workloads for employees experience measurable gains in employee output.

Employee well-being programs may comprise such aspects as flexible schedules, reasonable workloads, and mental health support. Implementation of these activities leads to improvement in employee performance as well as reduction of absenteeism, which, in turn, is a great labor utilization across the whole organization.

Moreover, the implementation of employee well-being initiatives is a powerful lever for closing the operational efficiency cycle. Employees who receive a good deal of attention and support from their managers become more motivated to keep up with high standards and constantly reach their targets.

9. Improve Communication

Good communication is one of the main factors that help to decrease errors, misunderstandings, and delays related to labor efficiency. There are tools and methods such as team briefings, standardized reporting, and visual boards that support communication within a team. Industry research reveals that firms that practice effective communication have higher output per labor hour.

Good communication can also lead to increased cooperation and staff performance, as workers will be able to quickly solve problems and exchange good practices. This frees up the time that had been wasted on other tasks and makes the work performed by the teams more efficient.

Moreover, efficient communication can pave the way for less-friction workflows and increased labor utilization, thus empowering the business to deploy its human resources in the areas that yield the greatest value.

10. Monitor and Adjust Continuously

For a long time, it is very important to keep on checking what is going on if you want to maintain a high labor efficiency. By looking through LER, output per labor hour, and rework rates, companies will be able to see the changes, and they will have a chance to adjust the processes before the inefficiencies become quite significant. What the experts say is that companies that work with continuous improvement cycles are always at a higher level of operational efficiency and productivity than their competitors.

By using this method, managers can find out which way is the most efficient one, training can be better, and scheduling can be more accurate, thus workforce productivity will be at its maximum. Employees will receive clear expectations and measurable goals, which will help them to improve their performance constantly; thus, employee performance will improve consistently.

Moreover, continuous adjustment is a winning strategy in labor efficiency as it guarantees the sustainability of labor efficiency improvements, thus it helps companies to keep up with the competition, reduce costs, and increase output.

These ten strategies offer huge potential for labor efficiency improvement to unfold within an organization and thus create a path for higher productivity to be achieved with the same workforce. Measurement, process optimization, and employee support are the key elements that will lead to lasting gains in workforce productivity.

How to calculate labor efficiency?

It is very important to calculate labor efficiency if you want to understand how your labor force is able to convert labor input into output. The most popular metric used for this is the Labor Efficiency Ratio (LER), which basically means a ratio of the standard hours required for a task to the actual hours worked.

Labor Efficiency Ratio Formula:

LER (%) = (Standard Hours for Actual Output ÷ Actual Hours Worked) × 100

Example:

If producing 1,000 units should take 500 hours (standard hours), but your team actually worked 560 hours:

LER = (500 ÷ 560) × 100 = 89.3%

An LER of 100% means perfect efficiency, above 100% indicates employees are completing work faster than expected, and below 100% highlights inefficiencies.

Other useful metrics to track labor efficiency include:

- Output per labor hour – measures productivity per hour worked.

- Labor efficiency variance – identifies deviations between expected and actual labor usage.

By calculating labor efficiency regularly, organizations can pinpoint bottlenecks, optimize workflows, and improve overall workforce productivity.

What is Labor Efficiency Variance Formula?

Labor Efficiency Variance (LEV) represents a difference between the actual hours worked and the standard hours allowed for the output produced, which is then multiplied by the standard labor rate. This KPI is very helpful for organizations to reveal inefficiencies in workforce performance as well as in-process execution.

Formula:

Labor Efficiency Variance = (Standard Hours – Actual Hours) × Standard Rate

Example:

If a task’s standard hours = 500, actual hours worked = 560, and the standard labor rate = $20/hour:

LEV = (500 – 560) × 20 = (-60) × 20 = – $1,200

A negative variance signifying that the number of hours used was more than expected shows inefficiency, while a positive variance indicates that employees finished the work quicker than the standard and thereby reflects higher labor efficiency.

Practicing the LEV frequently enables companies to locate their process bottlenecks, enhance the efficiency of their workforce, and make labor utilization more efficient, which is, in fact, one of the great ways of increasing overall operational efficiency.

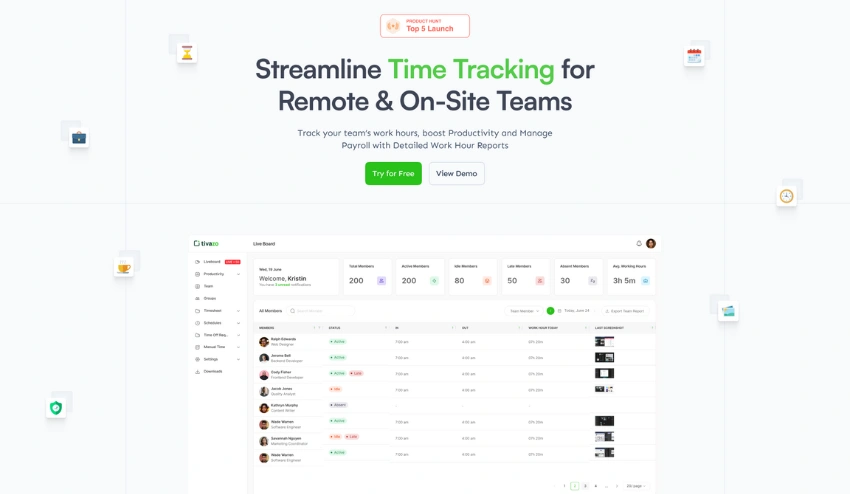

Boost Labor Efficiency with Tivazo: Here’s How

Tivazo is a fully-featured employee monitoring and time tracking system that is suitable for both remote and on-site teams. Organizations can get real-time updates on how labor hours are being utilized with the help of Tivazo and, therefore, can raise labor efficiency, streamline workflows, and improve labor productivity.

Key Features:

- Time Tracking – Accurately record hours worked to identify inefficiencies and improve labor allocation.

- Team Management – Assign tasks, monitor progress, and ensure optimal labor utilization across projects.

- Employee Monitoring – Gain visibility into employee activity to reduce idle time and enhance work efficiency.

- Live Screenshots – Track real-time activity for accountability without micromanaging.

- Performance Insights – Analyze productivity trends and identify opportunities to improve employee performance.

- Timesheets and Reports – Generate detailed reports to measure labor efficiency ratios and make data-driven decisions.

Conclusion

The point of labor efficiency is to raise it to a maximum of productivity while the hours of labor that go to waste are kept at a minimum. That measure will be an hour in which the worker will bring value. The excelled productive worker will be continuously lifting the bar of operations. By implementing such policies in practice and using tools like Tivazo, organizations can turn working hours into hours of real value.

The enhancement of labor efficiency is not a one-time act of magic but rather a continuous undertaking that eventually leads to an increase in output, a reduction of labor costs, and the creation of an engaged workforce. The question that comes next is whether you are willing to start optimizing your team’s labor efficiency right now.