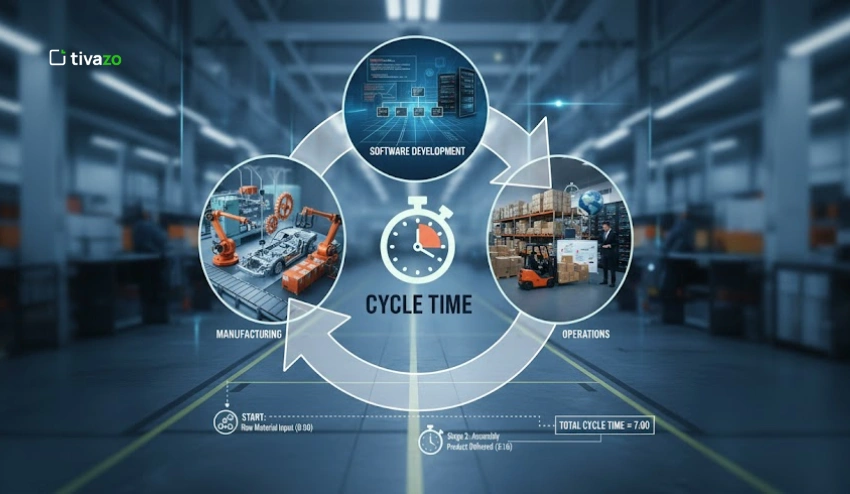

Productivity issues in both manufacturing facilities and software development teams tend to have a single root cause, which is cycle time. With the increase in the cycle time, the delivery is sluggish, the costs are higher, and customer expectations are more difficult to fulfill.

Cycle time is the time interval in which a unit of work is completed. In contrast to lead time or throughput time, it pays attention to the speed of performance and process efficiency, reveals the bottlenecks, unnecessary work-in-progress, and bad flow efficiency.

Organizations enhance production throughput, decrease software delivery times, and minimize time to market by examining and minimizing cycle time. It is a fundamental indicator of lean production, optimization of processes, and continuous improvement.

👉You May Also Like: 7 Smart Ways to Eliminate Operational Bottlenecks Fast

What is Cycle Time?

The time spent on completing a single unit of work in a process is known as cycle time. It is a measurement of the duration of a task, product, or feature to be created after work is actively started.

In production, a cycle time is a measurement of the time required to make a single unit or a completed product at the production line. It is used in software development to measure the time that a task, user story, or feature takes to pass through the development process to deployment.

Cycle time is one of the key performance indicators that can be applied to measure the efficiency of the processes, detect bottlenecks, and enhance production throughput. Reduced cycle time implies accelerated delivery, improved resource usage, less work-in-progress, and improved productivity.

Importance of Cycle Time

Cycle time is an important part of the optimization of production efficiency and the betterment of the workflow. Firms that monitor and minimize the time of the cycle can have faster delivery, reduced costs, and customer satisfaction.

1. Enhances Production Efficiency

Shortening the cycle time also enables manufacturers and software teams to complete tasks in a shorter time without reducing quality. The time that is required by each process can be monitored to help companies identify bottlenecks and streamline operations. The management of cycle time has a direct influence on throughput and the overall operational performance.

Reduced cycle times also imply optimal use of resources. The employees, machines, and software procedures can be matched in a more efficient manner, minimizing time wastage and unwanted delays.

Moreover, there can be an enhancement in the cycle time, which will result in faster innovation cycles. Firms are able to react fast to the changes in the market and the needs of the customers, and they remain competitive in production and software development.

2. Reduces Operational Costs

Cycle time has a direct impact on the cost of production and delivering projects. Extended cycle times raise the costs of labor, material, and overheads, whereas the optimised cycle times reduce the unwarranted expenses.

Monitoring cycle time also allows businesses to make decisions based on data. The step-by-step analysis allows companies to identify those points where the cost can be reduced without compromising quality.

Reduced cost of operations enhances profitability and enables organizations to invest in expansion efforts. Effective cycle time management is a cost-saving and scalability investment.

3. Improves Customer Satisfaction

Reducing the cycle times will imply that the products or software updates will be delivered faster and, as a result, increase customer satisfaction. Customers become more trusting and loyal when they obtain high-quality output within a shorter amount of time.

It is because cycle time is monitored so that deadlines are always met. It gives predictability and openness to clients, which is particularly essential in the manufacturing supply chains and software releases.

By focusing on cycle time, companies would be able to retain a reputation of reliability and responsiveness. This builds the relationship with the clients and may result in repeat business and favorable referrals.

📖Read More: Customer Retention and Satisfaction: 5 Proven Strategies

4. Supports Continuous Improvement

Cycle time analysis is one of the major elements of continuous improvement models such as Lean and Six Sigma. Organizations use cycle time measurements and refinements to detect inefficiencies and initiate process improvements.

The iterative changes that can be made by constant observation will result in production delays being minimized progressively. This is a proactive method that lessens errors, rework, and enhances the quality of the process.

In addition, a culture of efficiency and accountability is established through a focus on cycle time. Performance measures are more visible to teams, which leads to teamwork and departmental innovation.

5. Enables Better Resource Planning

Monitoring the cycle time assists the managers in the effective allocation of human and technological resources. Realistic scheduling of the project and allocation of work can be done by knowing the duration of every activity.

Optimization of cycle time eliminates the bottlenecks through the efficiency of the use of machines, the software tools, and the employees. This will result in more efficient operations and productivity.

Moreover, enhanced resource planning minimizes tension and enhances the performance of teams. Having a good understanding of process schedules, firms are capable of delivering on time and at the same time uphold the desired quality standards.

Concisely, cycle time monitoring and optimization are the key to any organization aiming to enhance efficiency, cost reduction, and customer satisfaction. Cycle time is one of the priorities that help businesses to stay competitive and be able to grow sustainably.

Challenges of Calculating Cycle Time

It may not appear to be a difficult task to calculate cycle time; however, there are several challenges that may occur in businesses, which may compromise accuracy and efficiency. Be it manufacturing, production, or software development, the actual cycle time can only be known by ensuring that every process stage is meticulously measured.

1. Variability in Processes

Variability in workflows is one of the key issues. The amount of time spent on different products, tasks, or software modules may vary, and it may be difficult to achieve a constant cycle time.

This inconsistency may result in erroneous data, which influences production planning and performance evaluation. Lack of accurate monitoring of cycle time may lead to inefficiencies and bottlenecks in organizations.

Besides, further complications in calculating the cycle time may be caused by human factors, performance of the machine, or software system delays. These variations are important to note in order to make measurements and improve processes.

2. Lack of Standardized Measurement

The question of what the beginning and the end of the process are is a thorn in the flesh of many companies. In the absence of standardized measurement criteria, cycle time may be calculated differently by teams or departments.

In manufacturing, the results of counting setup time, processing time, and wait time may be misleading because of the inconsistency in counting. In the same manner, in software development, testing and debugging steps are either included or not, and this influences the overall calculation.

Unified metrics are needed to compare the cycle time of different projects, find the bottlenecks, and use them to improve the projects.

3. Data Collection Difficulties

Measurement of the cycle time depends on the right data collection. Manual tracking is subject to inaccuracy, whereas automated systems might need expertise and investment.

Unstable or incomplete data may result in making wrong decisions on production efficiency and resource allocation. Business organizations should have good mechanisms for documenting the cycle time at each point of the process.

Efficient data collection will not only assist in the calculation of the cycle time but will also assist in identifying the areas that can be improved in order to minimize delays and optimize the working processes.

4. Complex Interdependencies

There are numerous production and software processes that are characterized by a number of interdependent tasks. The cycle time in these environments is not easy to compute since the setback in one area might have an overall impact on the workflow.

These interdependencies are important to comprehend perfectly how to measure the total cycle time and which stage is the most important in causing delays.

Through process interconnection analysis, businesses may make specific improvements and streamline their operations, as well as increase overall productivity.

5. Dynamic Changes in Workload

The cycle time may vary following changes in workload, seasonal changes, or software changes. The high level of changes is not favorable in terms of measurements over time.

A business should modify the cycle time tracking techniques to be dynamic to capture the changing situations, but still offer actionable details on how to enhance efficiency.

Flexibility in the method of calculation and regular monitoring of the data will keep the data on cycle time relevant and useful in decision-making.

Although the calculation of the cycle time is a complicated matter, variability, standardization, data collection, interdependencies, and alterations of the workload should be tackled. By breaking these barriers, organizations will be able to maximise the processes, minimise delays, and increase overall productivity.

What is the Formula for Calculating Cycle Time?

Cycle time is a critical metric in manufacturing, production, and software development that measures the total time taken to complete a process from start to finish. Accurately calculating cycle time helps businesses identify bottlenecks, optimize workflows, and improve productivity.

The most commonly used formula for cycle time is:

Cycle Time = Total Production Time / Number of Units Produced

Where:

- Total Production Time = Total time spent on production or software task execution.

- Number of Units Produced = Total units manufactured or software tasks completed in that period.

For processes with multiple steps, cycle time can also include setup time, processing time, and wait time to provide a more accurate measurement. By tracking this metric, companies can reduce delays, streamline operations, and enhance overall operational efficiency.

Cycle Time vs. Lead Time

| Cycle Time | Lead Time |

| Measures the total time required to complete a process or produce a unit from start to finish. | Measures the total time from receiving a customer order to delivering the finished product or service. |

| Focuses on internal process efficiency, production speed, and workflow optimization. | Focuses on customer-facing delivery time, order fulfillment, and overall supply chain performance. |

| Includes processing time, setup time, and waiting time within the production or development cycle. | Includes order processing, production time, shipping, and any delays in the supply chain. |

| The goal is to minimize cycle time to improve productivity and resource utilization. | The goal is to reduce lead time to enhance customer satisfaction and responsiveness. |

| Commonly used in manufacturing, production, software development, and operations management. | Commonly used in manufacturing, supply chain, logistics, and project delivery management. |

| Measured as Total Production Time ÷ Number of Units Produced. | Measured as time from order placement to product delivery. |

| Optimized by streamlining workflows, removing bottlenecks, and implementing Lean or Agile practices. | Optimized by improving coordination, automating order processing, and enhancing logistics. |

📖Read More: Cycle Time vs Lead Time: 2 Powerful Metrics for Efficiency

How to Reduce Cycle Time

The shortening of cycle time is critical in enhancing productivity, efficiencies, and overall operations in manufacturing, production, and software development. Businesses can also achieve quicker outcomes through the identification of bottlenecks and the optimization of workflows without compromising the quality of the work.

1. Streamline Processes

Breaking down the workflow process can help you discover the parts of your workflow that are non-essential or time-consuming. Automation of procedures cuts out redundancies and is a way of having smooth production or development cycles.

Standardized procedures enable the teams to carry out tasks more consistently and minimize the difference in cycle time. This leads to increased throughput and efficiency with time.

These processes can also be automated using tools and software to perform the repetitive tasks and leave the employees with high-value duties.

2. Implement Lean and Agile Practices

Lean or Agile-like approaches can be considered in minimizing the time of the cycle with the emphasis on efficiency, iterative nature, and waste removal.

Lean production methods, such as 5S, Kaizen, and value stream mapping, are useful in the manufacturing process to determine delays and streamline processes. Agile sprints and continuous integration accelerate the process of software development.

The process of reviewing and refining processes should be done regularly to have a cycle time as low as possible without compromising on quality.

3. Optimize Resource Allocation

Making the correct distribution of people, machines, and technology will minimize idle time and speed up the tasks that will be completed.

Managers can avoid bottlenecks and smooth operations by monitoring the distribution of workloads and dependencies among tasks.

Resource planning is optimized to enhance the productivity of employees and throughput levels, which is also a contributor to the reduction of cycle times.

4. Monitor and Analyze Data

Regular monitoring of the cycle time data will allow for revealing the scope of improvement and the effectiveness of the applied measures.

The basic measures like processing time, wait time, and setup time will give an idea about the bottlenecks and inefficiencies.

Organizations can make decisions using data, make specific improvements, and continually decrease cycle time.

5. Encourage Continuous Improvement

Establishing a culture of consistent enhancement encourages teams to find out what is not working and propose improvements.

Frequent feedback, training, and performance reviews are useful in keeping the focus on the minimization of the cycle time in all departments.

Accurate continuous improvement will also minimize the cycle time, besides improving the overall customer satisfaction, quality, and productivity.

Businesses can greatly reduce cycle time by increasing the efficiency of processes, introducing Lean and Agile techniques, increasing resource utilization, tracking data, and promoting continuous improvement. This results in a quicker delivery, reduction of costs, and better operational efficiency in manufacturing, production, and software development.

What is Cycle Time in Manufacturing?

In manufacturing, a cycle time is defined as the total time taken to make one unit of a production process that commences at the start-up point and ends with the production of the unit. It is a very important parameter that is applied to gauge operational efficiency, to identify bottlenecks, and to streamline production channels.

Cycle time encompasses all the records of production, which include setup time, processing time, and waiting time. Cycle time enables the manufacturers to trace the speed of the products on the production line and identify where there are delays, so that they can be improved specifically.

Minimised cycle time in production results in not just increased throughput, but also reduced costs of operation, better utilisation of resources, and increased productivity. A firm with good management of the cycle time can react more quickly to the customer needs, attain a competitive edge, and be more profitable.

What is Inventory Cycle Time

The Inventory cycle time is used to measure the amount of time an inventory spends in all the supply chain stages, starting with the receipt of raw material, all the way to the delivery of finished goods.

It aids companies in tracing the movement of stocks, detecting wastage, and managing stock levels efficiently. A shortening of the inventory cycle time enhances the cash flow, lowers storage costs, and creates better performance of operations.

The ability to monitor inventory cycle time enables the companies to optimize the supply chain processes, react more quickly to the demands, and be more in control of the processes of production and stocks.

What is Cycle Time in Operations Management?

The cycle time in the operation management is the total time spent on an individual task, process, or service to be finished.

It is one of the main measures of efficiency, determining bottlenecks, and enhancing workflow both in manufacturing and service operations.

Through tracking of cycle time, the managers are able to optimize processes, resource allocation, and productivity, and they can guarantee faster delivery and maximized operation performance.

Conclusion

In conclusion, cycle time is an important measure in manufacturing and production, software development, and operations management, as it has a direct influence on performance, productivity, and customer satisfaction. The accurate measuring and examination of cycle time enables organizations to find out the bottlenecks, to optimize the working process, to decrease the costs of operations, and to improve the use of resources. Whether it is the cycle time of the inventory, production line, or the completion of tasks in the software projects, reducing the cycle time offers a chance to deliver faster, reduce processes, and become more responsive to the market needs.

By making cycle time a priority in the continuous improvement strategy and Lean or Agile initiatives, the company will guarantee the continued growth, increased throughput, and competitive advantage in the modern business world, which is fast-moving.