Every business faces the challenge of slowdowns. There is a buildup of work. Deadlines are not met. The business feels overwhelmed. The common denominator of all of these issues is the presence of a bottleneck. Knowing what a bottleneck is is the first step towards eliminating the problem.

A bottleneck is a constraint that faces every business. It does not matter if you own a manufacturing business or a service business. A bottleneck is a constraint that limits your business from reaching its full potential. It limits you from increasing the speed of delivery of your products and services.

The good news about a bottleneck is that it can be eliminated. Once you know what the problem is, you can take steps to solve the problem.

This guide explains bottleneck analysis and shows you how you can improve the productivity of your business.

What is Bottleneck Analysis?

Bottleneck analysis is a way of identifying constraints within your workflow. It helps you pinpoint the exact areas that are limiting your potential and causing your workflow to slow down.

In this approach, your workflow is mapped and the performance rate at each stage is measured. This helps to identify the areas that are causing delays. It is the weakest link in your workflow that is causing your whole system to slow down.

Once the problem has been located, it can be fixed. This makes your whole system operate more smoothly and efficiently.

Definition of a Bottleneck in a Process or Workflow

A bottleneck is a point within a process that slows down the workflow, similar to water being constricted at the neck of a bottle. A single point within the process can cause the entire workflow to be slowed down, and your team will be waiting on it.

How Bottlenecks Occur

There are several ways that bottlenecks can occur:

- Having limited resources: Not enough people, equipment, or budget to get the job done.

- Approval bottlenecks: tasks waiting for approval in someone’s email inbox.

- Task dependencies: tasks that cannot be started until other tasks are completed.

- Skill gaps: Having only one person with the knowledge to do a particular task.

- Having poor planning: Unrealistic schedules and unclear priorities.

These are the causes of friction in the workflow. They are the causes that delay other parts of the operation.

The Impact of Bottlenecks on Productivity

Bottlenecks do not just slow things down; they have a ripple effect that touches all parts of your business.

The longer a bottleneck lasts, the more harm it causes. Your revenue declines, your customers become unhappy, and your employees become exhausted.

Delays and Slowdowns in Workflow

If a bottleneck occurs in the operations, everything will back up. Work will back up prior to the bottleneck as if it were a traffic jam.

Work that could be accomplished in a few hours now takes a few days. Simple tasks take weeks instead of a few days.

Your employees are not able to flow at their own pace. They are forced to wait instead.

Increased Workload and Employee Stress

The employees at the bottleneck point feel the brunt of the situation. They are asked to do the impossible and are under pressure to perform.

Meanwhile, the others are idle. They are waiting for the work to come to them.

It is the job of the process analyst to note that the level of stress among employees increases at the bottleneck points. Employee turnover rates are high at the bottleneck points.

Missed Deadlines and Reduced Output

A productivity bottleneck ensures that deadlines are missed. It is impossible to complete more work than the bottleneck point allows.

The clients are affected by the delays. They no longer trust you to complete the work.

Your overall output decreases. The business does more with more employees. The employees are busy, but the overall output of the business is lower.

The revenue also decreases because you are completing fewer projects. The business does not grow because you cannot increase your capacity.

How to Identify Bottlenecks

To identify bottlenecks, you need to observe your operations. Bottlenecks are obstacles to productivity, so you need to consider your data as well as your operations.

The production manager who identifies the bottlenecks on time will help you avoid big problems. Here are the ways to identify the bottlenecks.

Observing Task Queues and Delays

Take a walk around your working area and look for the bottlenecks. A physical or virtual queue will help identify the problem areas.

- Increasing Backlogs: Tasks are building up faster than they are being completed.

- Idle Resources: People or resources are waiting to be used.

- Rush Jobs: Constant urgency around a particular task or resource.

- Complaints: People are constantly complaining about the same delays.

You can ask your team members where they are waiting the most. They will know the problem area very well.

Mapping Workflows to Find Choke Points

The process of process mapping creates a picture of how work flows. You map out each step, from start to finish.

This method of finding choke points in a workflow shows how tasks are connected. The connections between tasks are clear.

You also mark how long each step takes. Highlight how much work sits idle between each step. The choke point becomes obvious. One step takes much longer than all the other steps.

Using Metrics and Data

The truth comes in numbers. Workflow management software tracks how work flows through your system.

The key metrics are:

- Cycle time: How long each task takes, from start to finish.

- Wait time: How much work sits idle between each step?

- Throughput: How much work you finish in a certain amount of time.

- Utilization rates: How much each resource is used versus its potential usage.

Time tracking shows you where your hours are going. Throughput analysis shows you what your real limits are.

The process bottlenecks show up clearly. One step takes longer or has a lower completion rate.

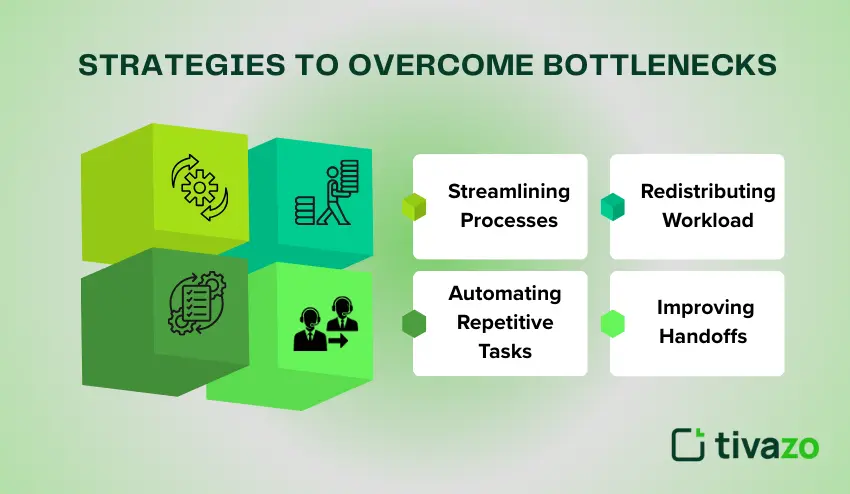

Strategies to Overcome Bottlenecks

Now that you know what the bottleneck is, the next thing to do is to fix it. The first strategy towards business process optimization is fixing the greatest constraint.

Small changes to the bottleneck can yield big improvements elsewhere. Here are some strategies to help you overcome the bottleneck.

Streamlining Processes

Identify any redundant processes at the bottleneck. Get rid of any process that does not add value. Simplify the approval process. Reduce the number of approvals required for any process. Avoid duplicated efforts. Ensure that you are not duplicating efforts.

Develop standards to make the process easier. Develop templates and checklists for any process.

Even the smallest improvements to the bottleneck will yield big improvements. Saving five minutes on every process may not seem like a lot, but it does add up.

Redistributing Workload

Don’t allow one person or one machine to do too much of the work. Implement proper workload distribution by redistributing tasks across the team and resources. Provide training for all the people in the group so that all of them can do the critical work. This eliminates the single point of failure.

Recruit additional people for the overloaded jobs. Sometimes you need additional capacity in certain critical areas. Vary the schedules to fit the demand curves. This helps you deploy the resources where you need them the most.

The objective is to have a balanced capacity in the workflow. No area of the workflow should be consistently overloaded.

Automating Repetitive Tasks

There are also bottleneck analysis software and automation tools that can help you eliminate manual bottlenecks. Let technology handle routine tasks. Automate data entry, approval of routine requests, and report generation. Leave complex decisions to humans.

There are also process optimization tools that can help you optimize your processes. These tools can automatically dispatch work to the right people without the need for manual assignment.

There is also project management software that can help you minimize coordination efforts. Everyone is kept in the loop with status updates without the need for constant meetings.

Improving Communication and Handoffs

A lot of bottlenecks occur between steps, not within steps. Handoffs are a big contributor to bottlenecks, even if individual tasks are done quickly. Define ownership of tasks. Define ownership of tasks clearly, especially at handoff points.

Implement handoff procedures. Standardize handoff procedures by specifying what needs to be passed from one step to the next. Implement notification tools. Tools, not humans, should notify others of handoffs. Implement daily stand-ups.

Identify potential blockers with daily stand-ups, so they do not become major bottlenecks. Improving workflow management ensures that work does not get stuck between steps. Improved communication ensures that everything keeps moving.

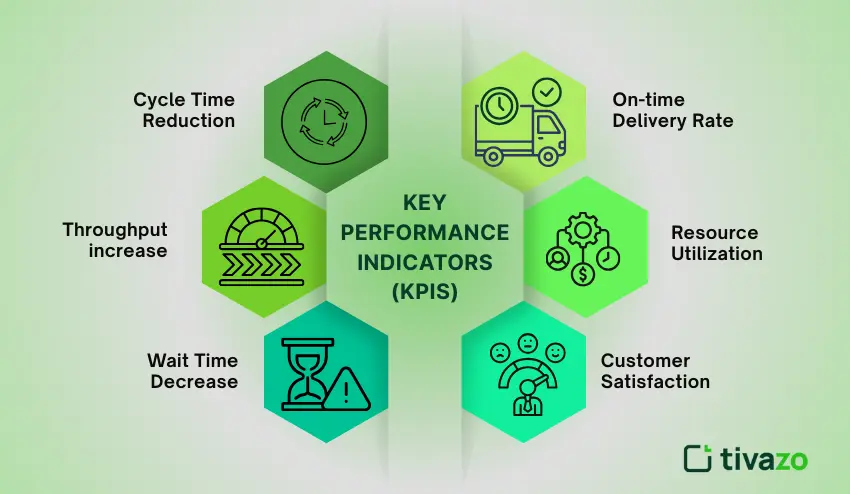

Measuring Improvement After Resolving Bottlenecks

Improvement should be measurable. Monitor your progress to ensure that your efforts have indeed made a positive impact.

Improvement in operational efficiency can be seen in terms of certain measurable factors. Keep an eye on these factors to measure your success.

Key Performance Indicators (KPIs) to Track

The following factors should be monitored before and after improvement:

- Cycle time reduction: How much faster work moves through the system.

- Throughput increase: How many more units can you complete per day or week?

- Wait time decrease: Less time spent idle between process steps.

- On-time delivery rate: A higher percentage of work finished by the deadline.

- Resource utilization: Better balance across your team or equipment.

- Customer satisfaction: Faster completion of tasks can improve customer satisfaction.

The results add up quickly. Small improvements can add up to huge improvements.

Continuous Monitoring for Ongoing Efficiency

Bottlenecks may change as your business evolves. What may work today may not work next quarter.

Establish regular reviews of your workflow. Bottlenecks can come and go. Monthly or quarterly reviews can catch problems early. Use capacity planning for future bottlenecks. Growth can create new bottlenecks.

Encourage your team to report any new bottlenecks immediately. This can prevent small problems from becoming big problems. The best organizations have made bottleneck analysis part of their culture.

Case Examples of Productivity Gains

Example of a Manufacturing Business

A furniture factory recognized that the bottleneck was at the sanding station. They decided to install one additional sander and train two more workers.

Result: Productivity increased by 40% in one month. This same group of people is able to produce much more work on a daily basis.

Example of a Service Business

A consulting firm recognized that the bottleneck was in the approval of proposals. They decided to implement a proposal template and approval system.

Result: Proposals are now approved within 4 hours instead of 5 days. This firm is able to close more business and win more proposals.

Example of a Software Business

A software development firm recognized that the bottleneck was in the code review process. They implemented a pair programming system.

Result: Releases are twice as frequent. The impact of bottleneck analysis on productivity is immediate.

All three examples illustrate the power of the principle. Focus on the constraint, and everything else improves.

Conclusion

Bottleneck analysis helps identify areas of your workflow that are stuck. It shows you exactly what is holding your team back from increasing their productivity. The steps involved in bottleneck analysis of your workflow are simple. Identify the area of the workflow that is stuck, measure the data, and solve the problem.

Small improvements in bottleneck areas of your workflow add up to huge results. Your entire workflow will speed up once you eliminate the slowest part of it. Don’t wait for your workflow to hit a crisis point before taking action. Review your workflow regularly to stay one step ahead of problems.

Start analyzing your workflow today. Identify your bottleneck and solve it to see your productivity soar.